I've been planning on improving my Ping Pong Ball Vacuum Cannon for several years, but never really gotten around to it. A couple of months ago, I started on the redesign. Most of the changes were small, but overall they worked out well in a slightly shorter device.

Concept

A Ping Pong Ball is placed at the end of aPVC pipe. The ends are covered with mylar. A soda can is placed near the other end. The pipe is evacuated. The far end is ruptured. The Ping Pong ball exits and rips a hole in the can.

Making the Cannon

First, I switched to transparent PVC. The stuff is expensive ($40+) and is not at your ordinary hardware store. Grainger sells it, though, and I picked up this 8 foot section at a local store in Arlington, VA. (I'm on sabbatical this year.) I also got a transparent connector. You can use opaque, but transparent is cool, especially for high speed cameras.

To connect to the vacuum pump, I drilled a hole 4 inches from one end using ???? which does a good job making a clean hole even in PVC. Using a pipe wrench I twisted in a short 3 inch long, 1 inch diameter brass pipe with tapered threaded ends. The pipe itself cut threads in the relatively soft PVC. This seals pretty well but not perfectly. After everything was done (and tested), I kneaded some plumbing epoxy and pressed it around the pipe to give the connection some stability and make a slightly better seal.

I screwed a 1" brass gas valve to the pipe using Teflon tape. I close the valve before firing to protect the pump from in-rushing air. I attached a brass nipple to the other side of the valve also with Teflon Tape.

Tubing and Pump

The red hose is vacuum tubing. I had some given to me, but you can buy it here from Flinn Scientific.

This gets connected to a vacuum pump. I've been using scientific pump but didn't bring it with me from SF. I bought this small pump from Harbor Freight Tools for $150, and it has worked like a champ so far.

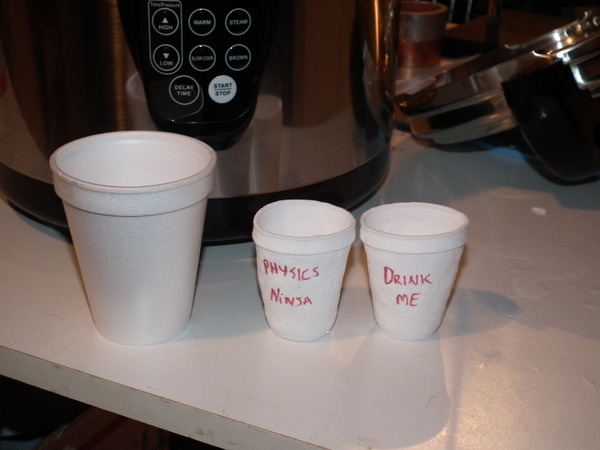

I use one star (cheap) standard 40 mm Ping Pong Balls and pieces of emergency blanket (mylar) to seal the ends. I got the idea from folks at BYU, but I see the link is dead. Sigh. What I do is cut a 10 cm x 10 cm square and pull it over the end so it fits smoothly. Here's a picture.

Then I push a PVC connector over to seal. Love this method. It seals better than tape, is much faster to apply, rarely gets sucked into the pipe, and when it does, it doesn't get stuck.

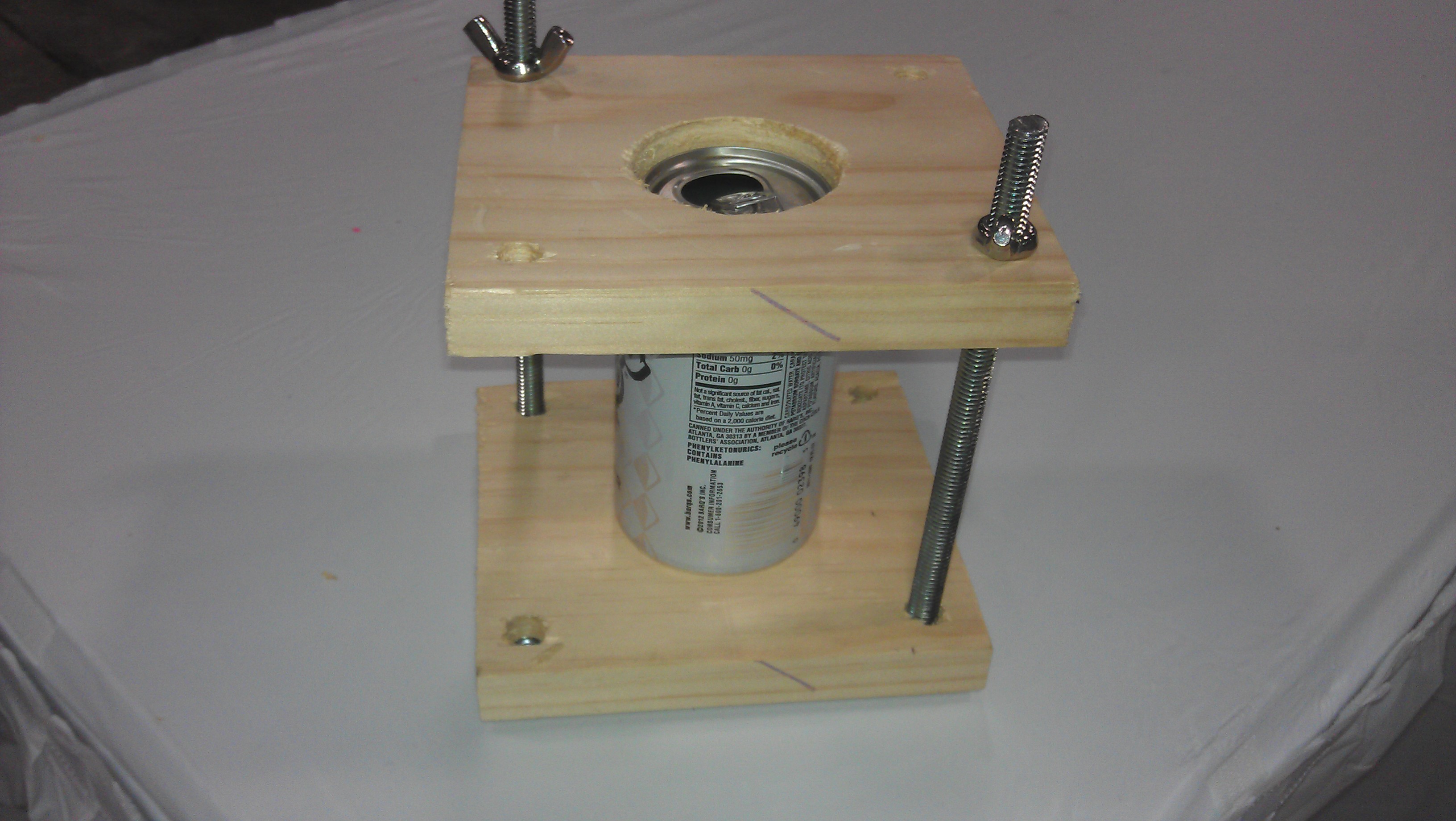

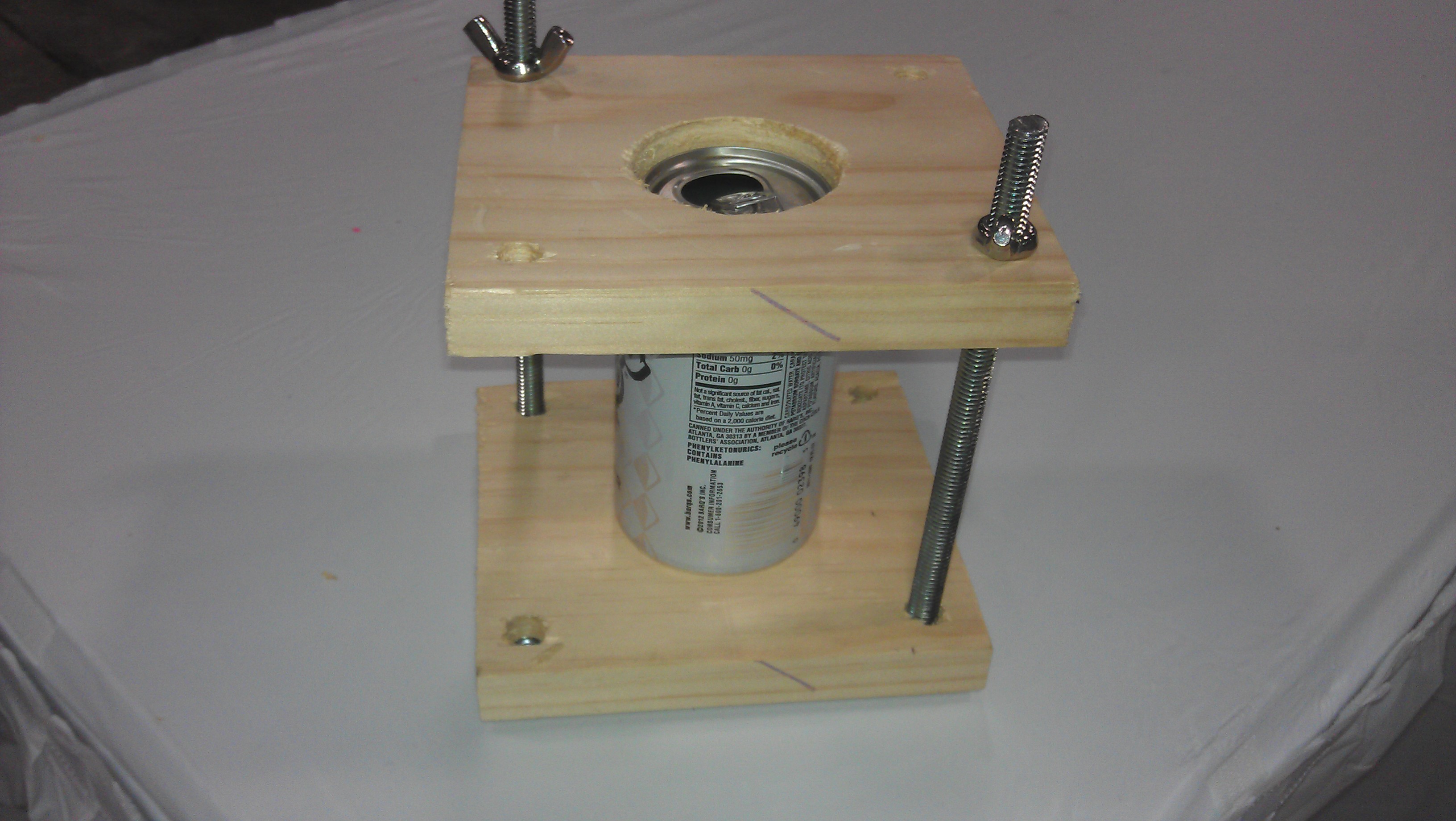

Can Holder

I used to use a bar clamp to secure a can to a lab jack, but I've upgraded and now have cut a holder.

The holder uses the fact that aluminum cans have a slanted top and bottom (a frustum) so that the can can be wedged and held in place.

To make the holder,

- Cut two squares of wood approximately 6 inches to a side and 3/4 inch thick.

- Cut a two inch hole in the center of each square using a hole saw.

- Stack the two boards together so that the holes line up as close to perfectly as possible. Clamp together.

- Drill two 1/2 inch holes through both boards on opposite corners. I drilled four holes, but I've since discovered that two work just fine and makes it easier to clamp.

- Cut using a hacksaw two pieces of 3/8 inch threaded rod about 7 inches long.

- Unclamp the boards. Insert and pound in two 3/8 inch t-nuts in the orientation in the picture.

- Place the can so that the frustums slip into the slots. Tighten with two 3/8 inch wingnuts.

The fired ball has a lot of energy but not much momentum, so it isn't probably going to knock the holder over or move it far, but metal and pieces of ball can fly after the collision. I put up an explosion shield. It's overkill, though.

Some people make a holder that holds three cans. The ball tends to pass through the first two cans and get caught by the third. That works well, but I think that it's less dramatic than seeing a single obliterated can.

Thursday, May 3, 2012 at 11:35PM

Thursday, May 3, 2012 at 11:35PM  Pressure,

Pressure,  thermo plastics in

thermo plastics in  Demos

Demos